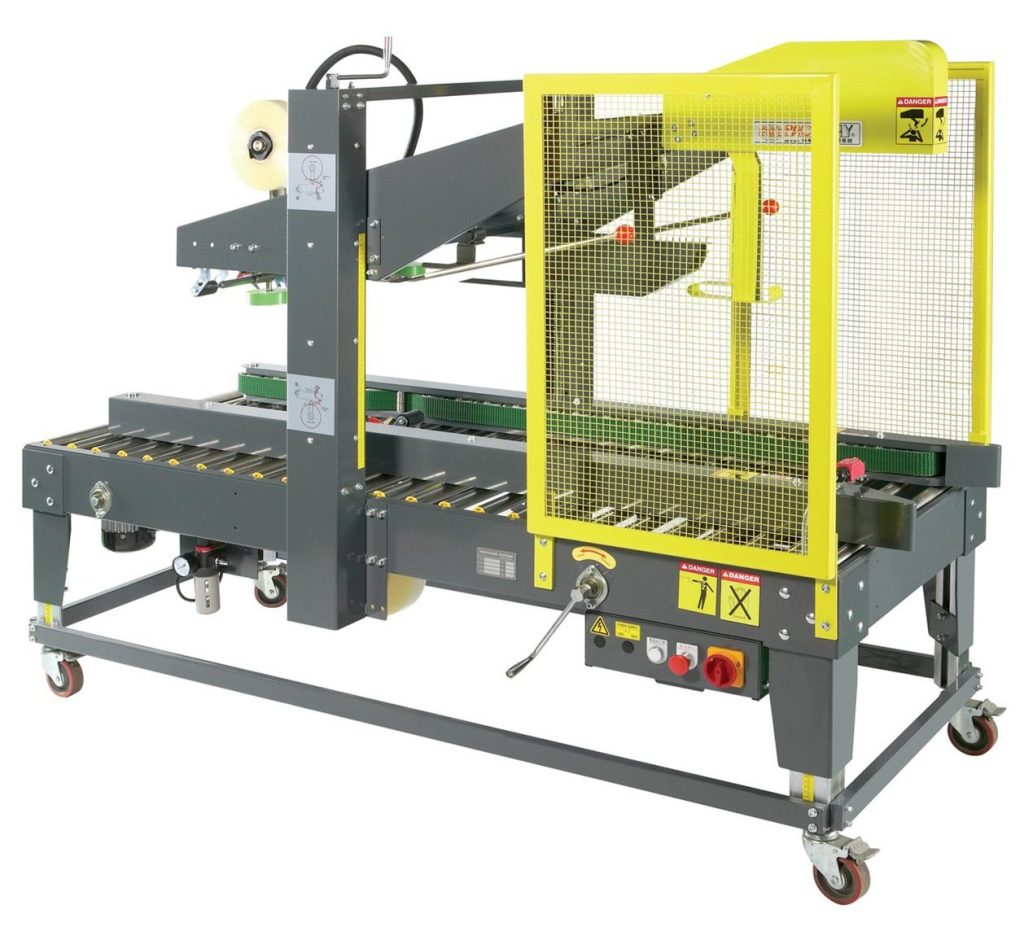

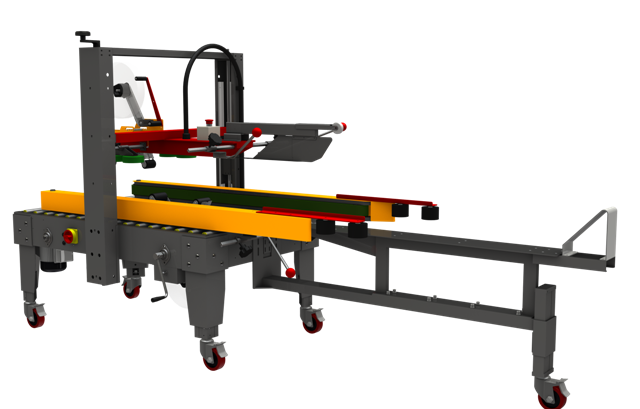

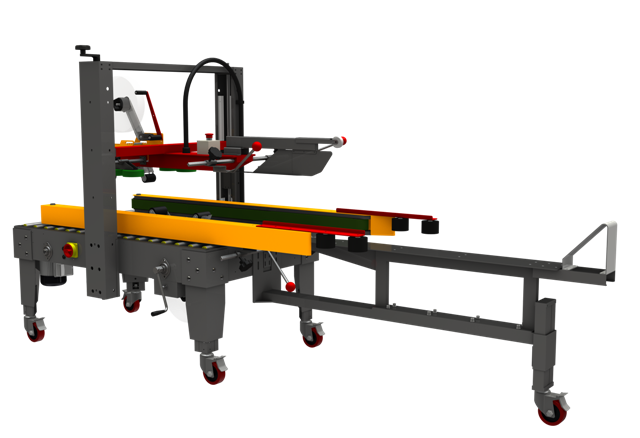

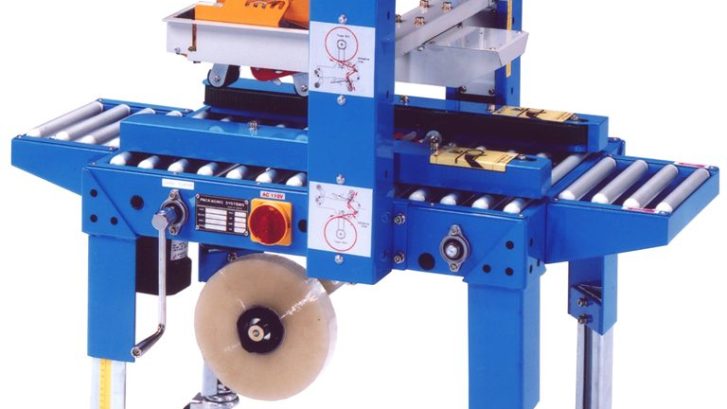

Top & Side Belt Drive Case Sealer (SPM-554TS)

Top & Side Belt Case Sealer (SPM-554TS)

The SPM-554TS uses a new tape head design incorporating a V-shaped plate (patented) designed to keep the tape straight and in position for consistent sealing of every carton. Separately driven side drive belts provide high precision, low noise andlong belt life. The overhead support is cushioned to adjust to small variations in boxes and prevent jamming.The SPM-554TS incorporates two additional top belts and is designed for heavy cartons as well as tall-thin cartons.

This machine is also available in stainless steel.

Voltage 110 V 1 PH 60 HZ

Power 10 amps Three motors, 555W

Sealing Speed 20M/min (66’) / min.

Cartons/Hr 2400 cartons per hour

Tape Width 2” or 3” (2” or 2.5” tape can also be used in 3” tape head with spacer)

Sealing Size L 150mm x W 200 – 500mm x H 120-500m

Shipping Weight 200 kg / 440 lbs

NOTE: Not suitable to use these machines if the carton’s height exceeds the length.